Every day, millions of people across the globe make use of public transportation. It is not hard to see why a reliable public transport system is crucial for any successful economy. Any failure in the system can have a wide-ranging impact and affect the lives of millions of people.

Challenges of Rail Tunnel and Track Inspection

Rail operators and asset owners face the increasing challenge of maintaining and inspecting railway tunnels and tracks efficiently and effectively. Traditionally, inspection is done manually. Outside of service hours, inspectors armed with torchlights walk miles and miles of tracks to conduct visual inspections of both tracks and tunnels. It is a tedious and time-consuming process. Besides, manual inspection also has its limitations such as prone to human errors and lack of efficiency.

Over time, if critical rail assets are not diagnosed accurately, and preemptive measures are not taken in a timely manner, equipment failure can result and operations disrupted, potentially affecting passenger safety. If such oversight happens, rail operators and asset owners will have to contend with high repair and maintenance costs.

Data-driven Autonomous Inspection Platform

Introducing the TunnelFox®, a purpose-built innovation developed to detect a wide range of track and tunnel defects. The first-of-its kind in Asia, the TunnelFox® is an intelligent, autonomous platform that can be set up within 15 minutes onsite and then let loose on the tracks to scour tunnels, scanning for anomalies such as cracks, dampness, bolt defects, and even signal quality.

The TunnelFox® is integrated with modern and advanced sensors and instruments to seamlessly collect real-time data and perform machine learning. The data can be further analysed for rail operators and asset owners to make better and timelier decisions to perform maintenance and repairs. In addition, the versatile TunnelFox® can take on any module or payload depending on the data collection requirements.

As a modern platform capable of self-navigation at pre-designated inspection areas, the TunnelFox® also has enhanced safety bumpers, with dedicated LIDARs and ultrasonic sensors for obstacle detection as well as a fail-safe brakes system.

The TunnelFox® never suffers from human fatigue as it detects fine cracks on rail tracks and tunnel surfaces that are easily negligible or not visible to the human eye! In a particular case study conducted in Singapore, the TunnelFox® was able to ‘sniff’ nearly 200 0.3mm cracks, whilst manual inspectors did not identify any in the same sampling area.

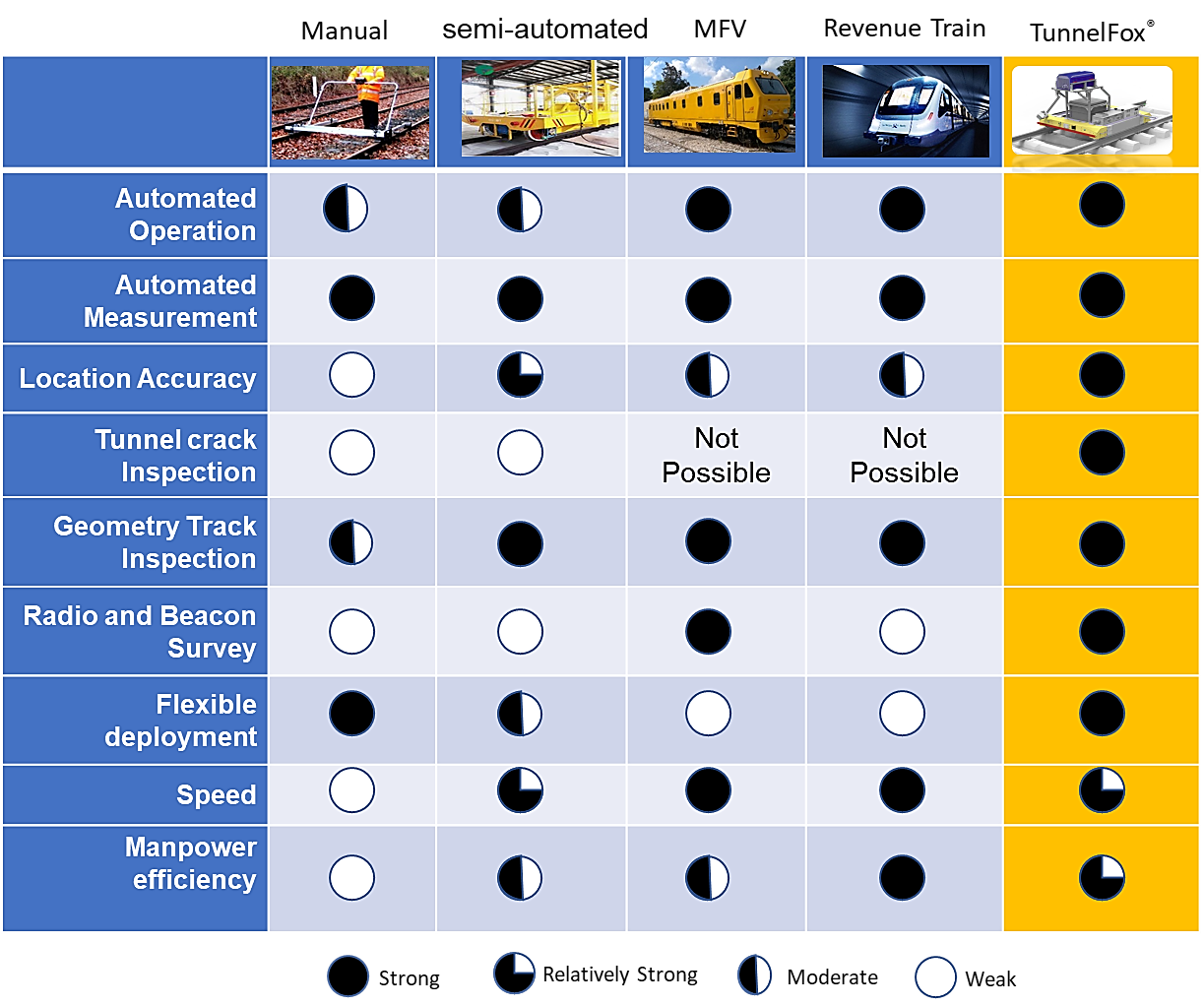

Here is a comparison of TunnelFox® against other rail inspection methods:

Enhances Safety, Reliability and Sustainability

As the world’s metro network continues to grow at 1,400km annually to 2022, a trend that is expected to persist into a post-carbon world, public transport will become even more essential.

Operators will have to operate smarter and more efficiently to overcome new operational and maintenance challenges, as they manage escalating ridership and demands for high quality and reliable services. We are already observing a general shift from the traditional emphasis on heavy engineering to software and data-handling skills.

Apart from emergency response and predictive maintenance, data analytics also uncovers redundancies, contributing to environmental sustainability. It also has a social impact, by enhancing commuters’ quality of life through efficient service.

The future of rail systems lies in advanced algorithms and data analysis software, which allow operators to harness and make sense of massive amounts of data, to enhance safety, reliability and quality of service to customers.

Leveraging new technologies will transform transport rail systems and commuters into a new era of rail travel that is more convenient, safer, economical and sustainable.

Learn more about TunnelFox®

Contact us

2-min read

4-min read